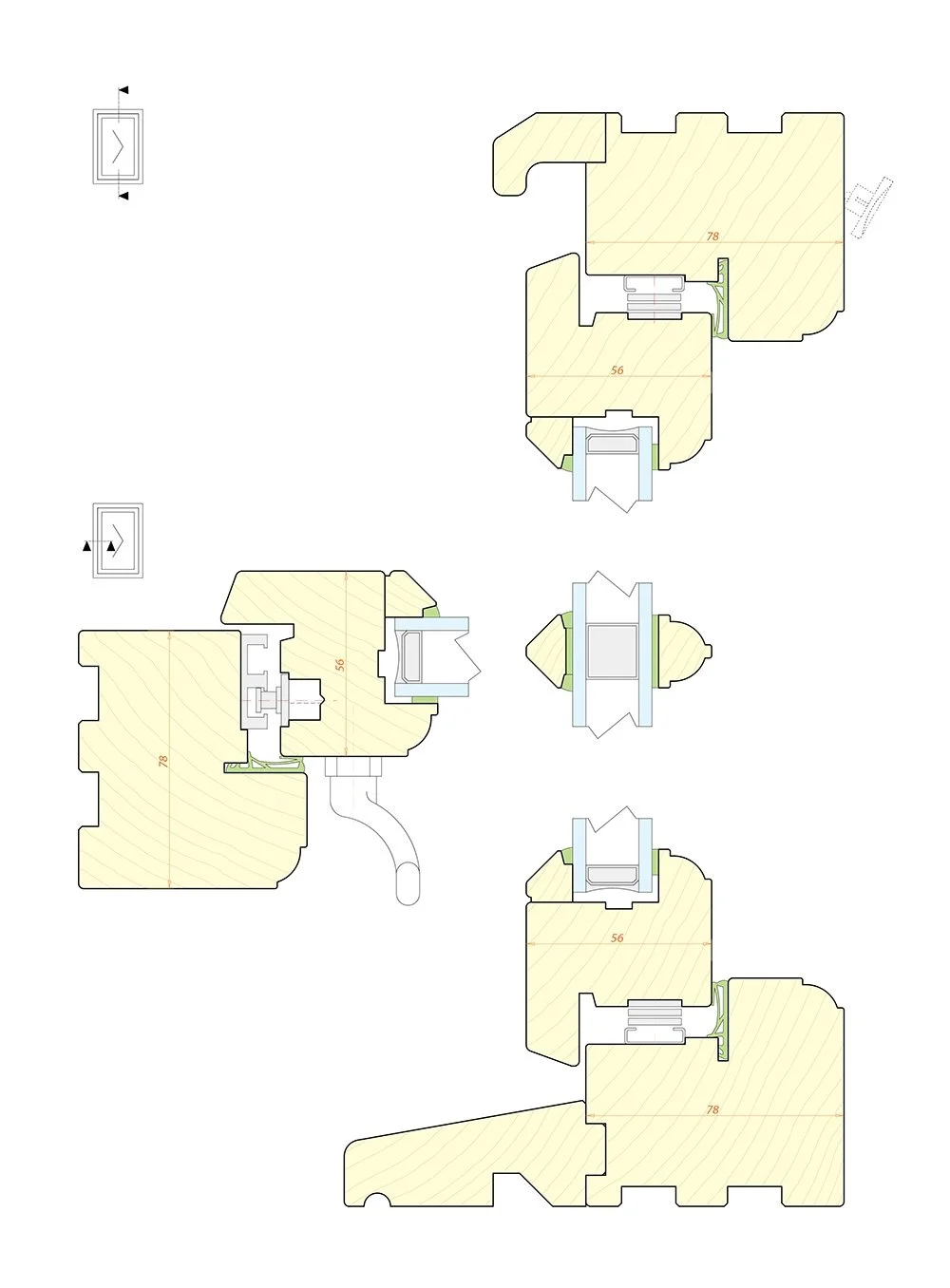

Stormproof Casement 78‑56 Timber Window Tooling

Stormproof Casement 78‑56 Timber Window Tooling Sub‑line: Engineered rebates and gasket grooves for unbeatable weather‑seal performance.

System Snapshot

The Stormproof Casement 78‑56 tooling pack produces a robust 78 mm frame partnered with a 56 mm sash, incorporating stepped weather rebates for exceptional exposure resistance. Designed for areas subjected to severe UK wind and rain ratings, the profile accepts double or triple glazing up to 32mm and integrates continuous compression gaskets.

Ideal for: Coastal properties, high‑rise developments, exposed rural sites, schools and public buildings seeking Class 4 air‑tightness.

Design & Performance Highlights

Offset ‘stormproof’ overlap: sash sits proud of frame to shed water and deflect driving rain.

78 mm Frame Depth: ample room for multi‑point locking and concealed trickle‑vents

Thermal U‑values: achieves as low as W/m²K 1.2, with triple glazing and warm‑edge spacer.

64 mm Sash Rebate: accommodates IGUs up to 40mm whilst keeping slim external sightlines.

Discrete Drip Groove: machined underside of the sash to minimise water run‑back.

Opening Variants Supported

Side‑Hung (Left / Right) – standard egress window for quick escape routes.

Top‑Hung – projecting hinge keeps sash clear of rain track when ventilating.

Fixed‑Light – non‑opening sash for matching transoms or sidelights.

What’s in the Pack

| Item | Purpose |

|---|---|

| Cutter stack – frame & sash profiles | One‑pass machining for repeatability |

| Storm‑rebate & drip‑groove knives | Create offset overlap and water‑shedding geometry |

| Lock & hinge recess cutters | Prepare pockets for common casement hardware brands |

| NC/CNC programme files (DXF/CSV) | Direct import to STP NC Positioner / CNC routers |

| Setup manual & run‑sheet | Spindle speeds, tool offsets, recommended feed rates |

Integration with Copenstick Machinery

The Stormproof Casement cutters can be ordered with the additional end‑scribing, single‑end milling scribe tooling

Ordering & Lead‑Time

Typical design and manufacture time: 7-9 weeks from sign‑off of approved drawings.

Worldwide shipping in custom foam crates; tooling arrives balanced, ready to cut.

Save Hours. Boost Profit.

Cut cycle times by up to 240 %, lower cost‑per‑sash, and ship more orders every shift—without expanding your floor space.

Made in Britain. Delivered worldwide.