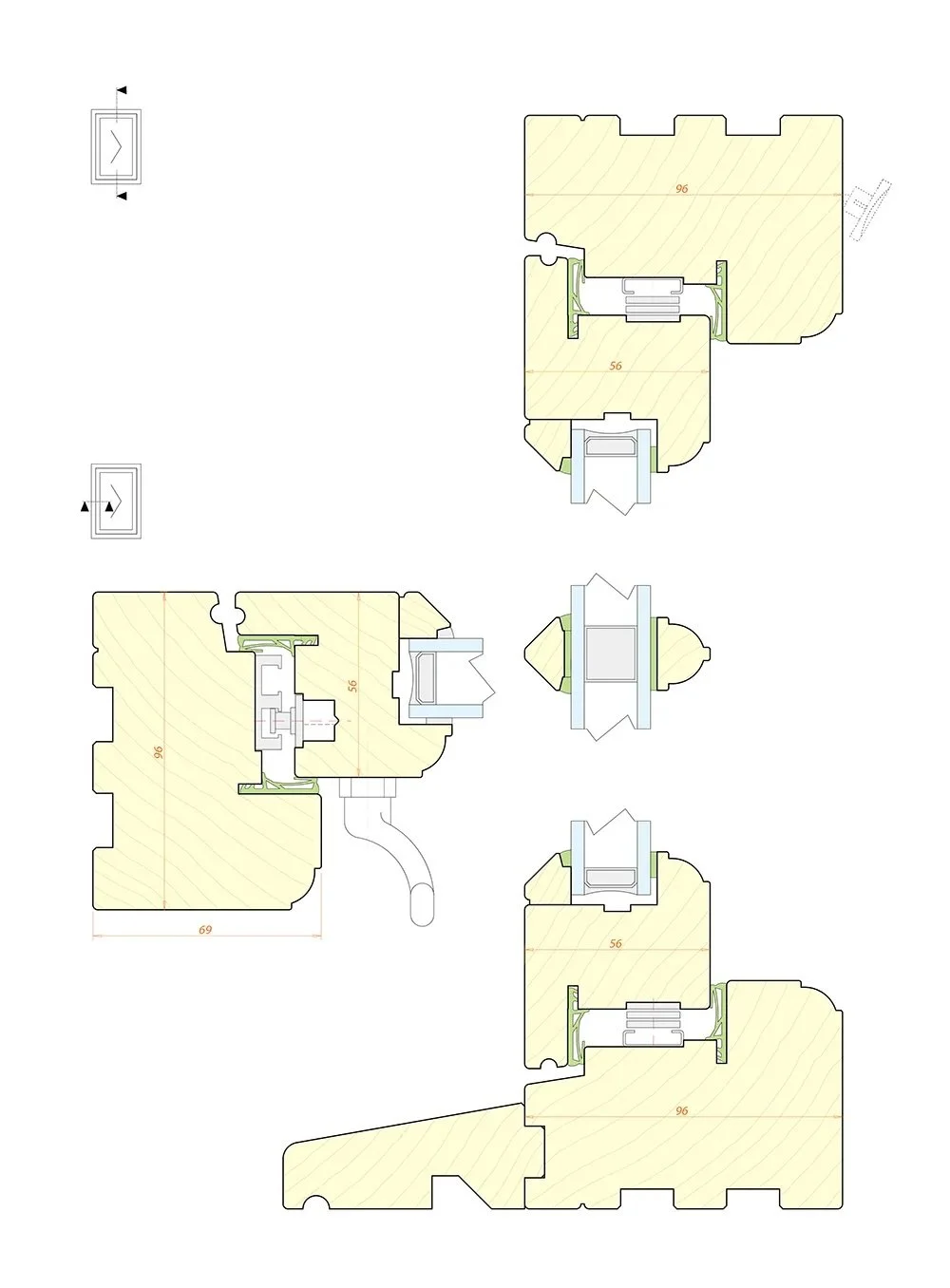

High Performance Flush Casement Timber Window Tooling

Authentic flush styling—with modern, low‑U‑value performance built in.

System Snapshot

Designed for workshops that demand traditional flush aesthetics and class‑leading weather performance, the High Performance Flush system tooling pack machines profiles capable of achieving U‑values down to U‑value 1.2 using triple weather seals and an engineered glazing rebate.

All cutters are balanced and supplied with full set‑up sheets for rapid, repeatable production runs.

Ideal for: new‑build dwellings targeting Part Q & Part L compliance, premium refurbishments needing enhanced thermal ratings, coastal or exposed sites demanding superior air‑and‑water tightness.

Design & Performance Highlights

Flush, Coplanar Sightlines: maintains the clean external face of heritage flush casements.

Triple Weather‑Seal Groove: accepts three compression gaskets for outstanding draught exclusion.

Glazing Rebate Depth: accommodates up to 24 mm / 28 mm GUs for improved thermal performance.

Low Drainage Threshold: profile includes hidden drainage path to meet modern moisture‑management standards.

Opening Variants Supported

Top‑Hung (Project‑Out)

Side‑Hung (Casement)

Fixed Light (optional sashless frame)

Specify hinge clearances and hardware codes at order so knife backs can be ground accordingly.

What’s in the Pack

| Item | Purpose |

|---|---|

| Full profile cutter stack | Machines sash & frame in a single pass where possible |

| Glazing bead knives (plant‑on & putty‑line) | Choice of modern or heritage bead finish |

| Drip‑groove router knife | Integrates concealed water‑shed below sash |

| NC/CNC program files (DXF/CSV) | Instant import to STP NC Positioner and compatible routers |

| Setup manual & run‑sheet | Step‑by‑step tool positions and spindle speeds |

Integration with Copenstick Machinery

The High Performance Flush Casement cutters can be ordered with the additional end‑scribing, single‑end milling scribe tooling.

Ordering & Lead‑Time

Typical design and manufacture time: 7-9 weeks from sign‑off of approved drawings.

Global shipping available; tooling arrives precision‑balanced and ready for first cut.

Save Hours. Boost Profit.

Cut cycle times by up to 240 %, lower cost‑per‑sash, and ship more orders every shift—without expanding your floor space.

Made in Britain. Delivered worldwide.